What is sustainability?

Sustainability is a discipline of science and social studies that looks to improve, protect, and nurture not just the environment, but businesses and human life as well.

But what is sustainability in the FMCG industry?

Business operations that produce minimal effect on the environment via eco-friendly, recyclable, and reusable packaging while also ensuring profits.

Why do you need to know this?

Global warming and climate change are an international issue and, as a society, we must take joint steps to safeguard our planet while keeping our industries and businesses in action.

We are aware of what we must do to protect the environment (we only have one Planet after all), be it recycling, reduction in energy consumption, or using environment friendly products and ideas. As industry leaders, it is our duty to minimize carbon emissions and set an example for other industries to follow.

Achieving this is not difficult provided we make use of renewable energy expertise, sustainable product development, and/or government subsidies and profitable schemes to install recycling units and green initiatives for manufacturing operations.

For the FMCG packaging industry, there are many ways to attain sustainability. Around 90% of FMCG packaging uses commodity plastics which are easy to obtain and mould while being food- and drug- compatible. Till recently, these plastics were made from virgin resin i.e. the fraction of lighter monomers (hydrocarbon bonds) obtained from polymerization of crude oil. FMCG has so extensively consumed plastics for packaging that we cannot imagine these goods without plastic. Although this has made our lives a lot easier, it has escalated pollution. But now, it is also possible to re-use these plastics for packaging.

Post-Consumer Resin is among the hottest emerging markets in the world of packaging. Every organization is now speeding up to achieve their sustainability goals to become a market leader for sustainable packaging and cut environmental damage. Let us deep dive into the various aspects of PCR.

Following are the aspects to focus on for sustainable development from an industrial point of view:

1. Post-Consumer Resin – Most commodity plastics used for packaging viz. PP, PE, PET, PS, etc. are from this polymer group. Usually, consumers throw them away. Recyclers collect them; segregate them into plastics, metals, wood, etc.; classify collected plastics into different polymer groups; and then treat them chemically into raw plastic resin for reuse.

Let’s think of plastic resin as a soft clay figure that we model into a certain shape, break it back into a stack of clay, and use it again to create a model. Some physical and chemical properties of the recycled plastic can be different from those of the original.

This should not stop us from recycling as it reduces the use of crude oil for making virgin plastic. Mining, processing, and use of crude oil all emit pollutants. Thus, post-consumer resin ensures re-use of an existing package via recycling and recreating the product for positive environmental impact.

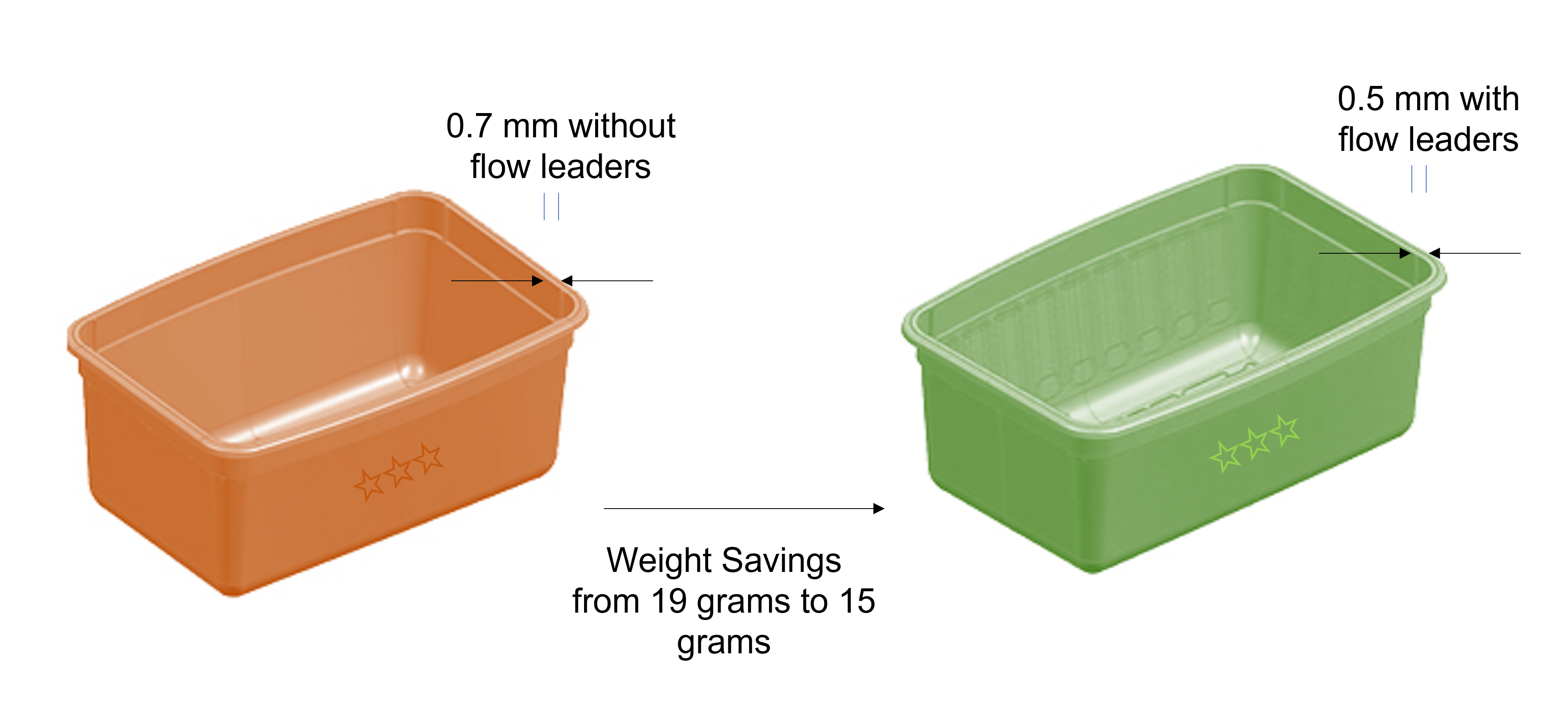

2. Sustainable design – Often, companies create packaging that has too many components, thick components, or multiple layers of plastic for aesthetics, durability, marketability, or innovation. This results in 10-30% excessive plastic usage. Such practices accelerate the use of virgin or recycled resin, which expands your company’s carbon footprint.

Regulations have targeted the increase in carbon emissions due to such excessive packaging. Capital expenditures have escalated for companies without sufficient sustainable infrastructure. To ensure minimal use of plastic into a packaging product, the effort must start from the beginning i.e. product design. . This could lead to higher margins and lesser harm for the environment.

3. Proximity – Many FMCG giants have spread their various manufacturing plants across various states or countries or even continents. This is usually done to acquire certain markets or take advantage of government policies. Optimizing your supply chain with a plastic package manufacturing plant at one location and the filling/assembly plant at a faraway location can deliver enormous cost, logistics, and quality advantages. However, the segregation results in excessive consumption of transportation fuel and greater usage of electricity for maintenance and storage of packages for stock building, which ultimately increase cost and pollution. Calculated changes to your technical processes and product design-development could yield enormous financial and ecological value in the long term.

EIPL is an expert in Sustainable product design and development.

Our Team provides Sustainable solutions right from product design, redesign, or innovation to implementation, and from the prototype phase to its industrial tool qualification. Our skilled and highly experienced team ensures utilization of up-to date technical capabilities and project management techniques in delivering the projects for market launch. We have several years of experience in implementing post-consumer resin (PCR) in production at optimized costs by design of the existing packaging products. This has given us an edge as we help clients rapidly attain a sustainability tag. Rigorous follow ups and data accumulation service is also provided for every project.

Moreover, we extensively assist in management and execution of R&D prospects for qualifying Dimensional, Functional and Ergonomic aspects of a product which accelerates the project timeline. We provide a detailed analysis of the process capabilities to ensure the compatibility of PCR grade packaging with Virgin grade packaging.

Our supply chain expertise has been extremely helpful to our clients in optimal relocation of their assets in relation to their suppliers. A thorough check of the vendor’s compatibility, plant’s design, supply chain documents, quotation, etc. is carried out for successful relocation.

We ensure dedicated resources for smooth communication over the course of the projects. Effective communication skills and people management are our key attributes to connect people across the globe for successful project delivery. EIPL promises excellent value addition, execution of responsibilities, and fully reliable services.

Our team has a global reach in injection moulding. We have acquired vast knowledge and experience, over last 14 years of working with global leaders of industries in India, and 42+ other countries.

Connect with us on www.efficientinnovations.in to know more!

Article by

Darshak Mehta

Project Manager

EIPL