Flip top plastic closures, also known as flip-top caps or flip-flap caps, are a type of plastic closure used for containers and bottles. They are called a “flip-top” closure because the lid can be easily opened and closed by flipping it open and then snapping it shut.

Used for packaging a wide range of products, from liquids to food items to personal care products, these closures are designed with a hinged lid that flips open and closed, providing a convenient way to access the contents of the container.

Materials

Flip top closures are typically made from thermoplastic materials, such as polypropylene (PP) and high-density polyethylene (HDPE). These materials are lightweight, durable, and easy to produce, making them an economical option for manufacturers. The closures can be manufactured in a variety of shapes and sizes to fit different types of containers and bottle neck diameters.

Design of Flip Top Closures

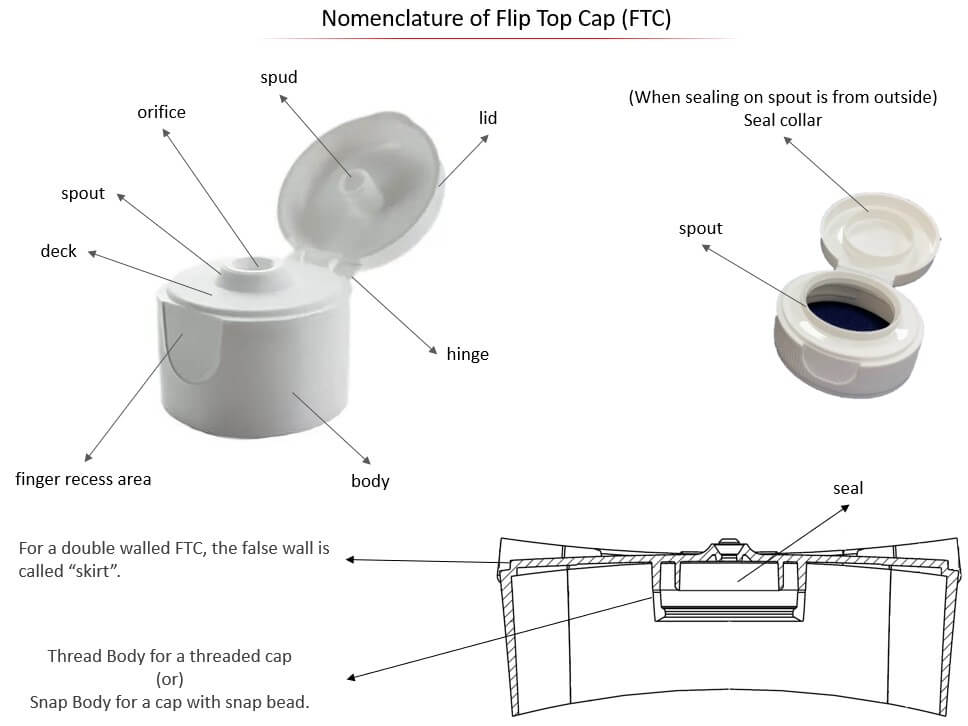

The design of flip top closures includes a hinged lid that is attached to the base of the closure by a living hinge. The hinge allows the lid to flip open and close. The closure also includes a sealing gasket that creates a leak-proof seal between the closure and the container. The design of the closure must ensure that the lid remains securely attached to the base and that the seal is tight to prevent spills and leaks.

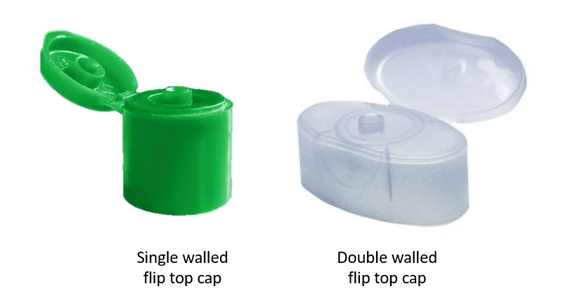

Flip top caps can be single or double walled closures depending on the type of flush desired on the bottle.

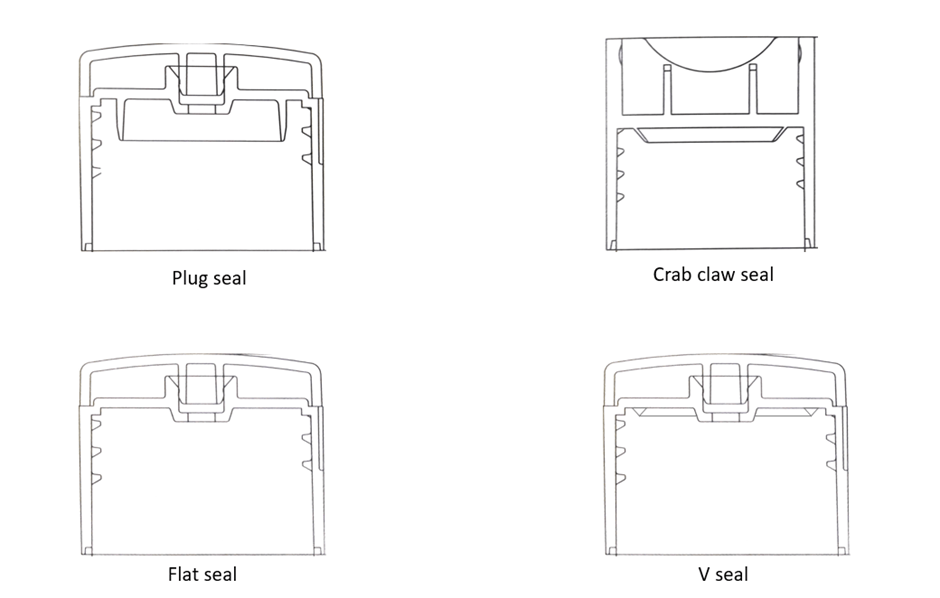

Design of the sealing system is important to ensure a leak-proof seal. Some of the popular sealing types used are plug seal, flat seal, crab claw seal, and v-seal. Details are as follows:

- Plug Seal is the simplest and most used sealing system. This seal fits inside the inner diameter of the bottle, thereby creating an excellent surface contact. Therefore, to ensure a good fitment, the ID of the bottle/ jar must be well controlled. Furthermore, the closing between bottle and cap must be perfect.

- Flat Seal has the land of the bottle directly connected with the deck of the cap. Since there is no additional sealing feature provided to arrest the leakage, packs with flat seal must be used only for high viscosity fluids.

- Crab Claw Seal is used with threaded caps. The seal is of a thin and flexible type which gets compressed against the land on the neck of the bottle. This creates a small surface contact when kept under sufficient pressure. This type of seal can be used for EBM bottles where the ID of the bottle is relatively higher as compared to ISBM bottles. All in all, the wall of the jar or bottle must be thick to have enough land for sealing.

- V-Seal, as the name suggests, has a V notch projection either in the cap, as shown in the image below, or on the land of the bottle. The notch under sufficient pressure will puncture and become slightly flat converting from a line contact to a surface contact.

Crab claw and V-seal are ideal for threaded closures, plug seal is a good sealing option for either threaded or snap lock closures.

Hinge designs

The design of the hinge is crucial to the functionality of the closure. The hinge must be able to withstand the repeated opening and closing of the lid, while maintaining its flexibility and ability to hold the lid securely in place. A common design for the hinge is a thin strip of material that is moulded into the closure, creating a flexible joint that allows the lid to move freely. This design is known as a “living hinge” and is made from the same material as the rest of the closure. Hinge designs can be:

- Flat Hinge or Dead Hinge has a flat strip of plastic with or without a cut. The cut reduces the section to enable the lid to bend on the hinge at a dedicated location.

- Butterfly Hinge, as the name suggests, has a butterfly shape. The central pivot forms the body and the thin plastic wings. These thin plastic wings act like a spring. Beyond a certain angle, the lid springs to the close or open position.

- Dual Axis Hinge is similar to butterfly hinge but without the central pivot.

- Strap Hinge has a strap at the centre of the hinge with two pivot hinges on the sides. This hinge too acts as a spring helping in the opening or closing of the cap.

Application Torque

This term is applicable to threaded caps and is an important consideration from the filling line point of view. If the application torque is deficient, then the the risk of caps opening up during the transit will be high. A good interference between the cap and bottle threads will assure the target application torque.

Factors that can affect the application torque are:

- Type/ profile of thread used for caps and bottles.

- Resin

- Masterbatch

- Surface finish and the resulting frictional force

- Product in the bottle as spillage on the bottle neck can occur on a filling line that is not completely controlled. This can result in deficient lubricating quality thereby reducing the torque force.

- Temperature at which the product is filled in the bottles and the resultant change in properties.

- Filling line speed or the application speed.

Capping Force

Amount of force required to place the cap onto the bottle is termed as capping force. This is applicable for caps with latch / snap bead. Normally the upper limit of capping is specified. This is either the max pressure the bottle can take based on the top load capacity (the load at which the bottle will buckle) or max pressure (not more than 80%) that the filling line chucks can exert.

Factors that affect capping force are:

- Design of the spud and orifice interference

- Resin

- Masterbatch

- Additives

- Processing parameters

- Filling line speed

- Product in the bottle

- Part temperature at the time of capping

Lid Opening Force

Quantity of force required for opening the lid is termed as lid opening force (LOF). The range for LOF of a cap must be carefully selected. Too low and the cap will easily open during transit resulting in leakage of pack. And too high an LOF will make consumers complain. A right trade-off is needed to achieve the target LOF.

Factors affecting the LOF are:

Design of the spud and orifice interference which depends on:

- Interference between bead and base diameter of spud and orifice

- Resin

- Masterbatch

- Additives

- Processing parameters

- Lid closing time [manual/ In Mould Closing (IMC)/ Out Mould Closing (OMC)]

- Part temperature at the time of closing

- The methodology of LOF measurement

Benefits of Flip Top Closures

- Ease of Use: The hinged lid of flip top closures makes it easy to access the contents of the container, reducing the risk of spills and leaks. This makes them ideal for use in a variety of applications, from packaging liquids to food products to personal care items.

- Cost-effectiveness: The lightweight and durable materials used in the manufacture of flip top closures, as well as their ease of production, make them an economical option for manufacturers and consumers alike.

- Customization: Flip top closures can be customized with different colors, designs, and logos, allowing manufacturers to create unique packaging that stands out on store shelves.

- Versatility: Flip top closures are available in a variety of sizes and shapes, making them suitable for a wide range of container types and sizes.

Flip top plastic closures are a versatile, cost-effective, and convenient option for packaging a wide range of products. Their ease of use, leak-proof design, and customization options make them a popular choice for both manufacturers and consumers. Flip top closures also support tamper evident sealing options. The use of thermoplastic materials in their construction makes them durable, lightweight, and easy to produce, which transforms into an economical option for manufacturers.

Efficient Innovations have decades of experience in working with numerous flip top caps of different shapes and sizes. Consult our experts at Efficient Innovations to facilitate the overall design and qualification process.